How To Sharpen A Blade

By Adelia Ladson

When you invest money in a quality knife or sword, you are just flushing it down the toilet if you don’t take care of it and perform regular maintenance to the blade. The most important maintenance task is sharpening. No point in having a blade that you let get too dull to use. After continued use, especially daily use, any blade will eventually lose its razor-sharp edge. Here, at BUDK.com, we have several high-quality sharpeners to remedy that.

Our Sharpen It Up Knife Sharpener is one of our most popular models and that’s largely because it is so compact that it can be taken and used anywhere. Whether you’re rescuing an extra dull blade or just doing a quick reconditioning, this pull-through sharpener will do the trick. It features both tungsten carbide rods and ceramic rods, plus, a fold-out diamond tapered rod. Simply pull the blade, in even smooth strokes, through the carbide slot to hone the blade and then do the same with the ceramic slot to polish it to a razor’s edge. Use the diamond rod by running it down the edge in even, smooth strokes. This will give your blade a tune-up. The mini, pull-through sharpener repairs and hones a variety of knives quickly and easily and the convenient lanyard hole allows you to attach it anywhere you need it.

When you want to get back to basics, the Japanese Water Stone is a method that’s been used for hundreds of years. The soft whetstone can be used on a knife or sword and it won’t become glazed or loaded with material from the blade it’s sharpening. New particles are constantly exposed as you work the knife, so the stone continues to cut consistently. It can be effectively lubricated with water, which forms a slurry with the worn material that sharpens and polishes the blade. Our water stone has a medium grit on one side and a fine grit on the other side. To use the Japanese water stone, first, soak it in water for about five minutes but never leave it immersed in water for much longer. Next, place it on a non-slip surface with the medium grit side up, then, place your blade flat against the stone and raise the spine to a slight angle, less than 45-degrees. Close one hand around the handle of the knife, place the other hand on top of the blade and push the knife down the stone in a smooth motion, going from tip to heel. After ten passes across the stone, lightly skim the side of the blade near the edge with your finger to feel for a burr. This is a slight raise in the metal, on the top side of the blade, that should run the entire length of the blade. It there isn’t one, continue your passes. If your blade is double-beveled, now is the time to switch to the other side and repeat. If not, then, move on to the finer grit on the other side of the stone. Make sure that you maintain the same angle, speed and pressure on the blade throughout the sharpening process. Rinse the blade of any debris before you repeat the sharpening process with the finer grit side of the stone. Your passes over the fine grit are getting rid of the burr that was raised with the coarser grit and, if you have a double-beveled knife, alternate sides of the blade with each stroke. When you’re done, wash your stone and wipe it with a soft cloth. Let it completely air-dry before you store it in its box. Just a note: It is a Japanese WATER stone. Never use oil or any other metal cleaner because it will absolutely ruin it.

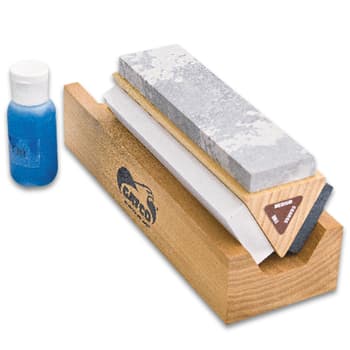

Another option in the whetstone family is the Natural Soft Arkansas Stone. The 100-percent Arkansas Stone was mined from novaculite quarries, then, carefully cut to size and skillfully finished to insure flatness. Novaculite, highly regarded by craftsmen worldwide, has a unique crystalline structure, which allows it to polish the cutting edge as it sharpens. Our Arkansas Stone is mounted on a natural wood triangle which provides an elevated work surface. The same sharpening process is used as with the Japanese stone, except it doesn’t need to be soaked in water before you use it. It can be used dry. Be aware, that with any type of whetstone, it will eventually become concave with use and must be flattened again to continue to be effective in sharpening. A flattening stone can easily be purchased specifically for this purpose.

Another classic method that’s been used for hundreds of years is a strop and, when you’re looking for the best, our Kriegar Double-Sided Hanging Strop is top of the line. It has two distinct stropping surfaces – an ultra-smooth, premium buffalo leather on one side and a coarser suede on the other side. The rough suede removes larger edge damage and the buffalo leather removes the tiniest imperfections. The 3” wide design allows you to strop the entire length of a traditional straight razor in a 90-degree pass, making it easier and reducing the uneven stropping that can result from using the “X pattern” that’s required for narrower strops. This brawny strop is perfectly suited for any knife including large bowie blades. One end of the strop features a swiveling hook, which allows you to flip from one side to the other seamlessly, without needing to unhook it. A stainless steel handle is on the opposite end. The most effective way to use a strop is after you have sharpened your blade, initially, with a whetstone. Stropping will get it to that next polished, razor-sharp finish your knife deserves. Use the hook to hang the strop on a fixed object, take the handle and stretch it out with one hand and take your knife in the other hand. In stropping, you are pulling the blade toward you, which is the opposite of what you’re doing in sharpening. Make sure to use the same angle of pull that you did push when you were sharpening the blade. Some people prefer to apply a honing compound to the strop first, but this is not necessary. The abrasive particles in the compound help show results more quickly when stropping. Note: Do not try to strop a knife with a serrated edge because it will destroy the strop.

After sharpening, to keep your blade at its maximum potential, make sure that you clean and protect it, too, so that the metal stays in top condition. Our Max Edge CLP Knife Lube is a must-have for your blade maintenance routine. It penetrates and spreads along metal surfaces into every pit and crevice to lift residue away, where it can be removed. The long-lasting lubricating film dramatically reduces adhesion of sand, grit or other abrasives, which cause wear and tear on the metal of your blade. Corrosion inhibitors, in the formula, prevent the formation of rust, while the unique boundary film protects metal surfaces from moisture and other contaminants. It’s well worth the time and effort to protect a blade that you’ve invested money in!